Strategic Analysis Tools

Strategic analysis tools conduct research on a company and its operating environment to develop a strategy. Some of the common factors of this process are: identifying and evaluating data important to the company’s strategy, determining the internal and external environments to be evaluated and using various analytic methods such as SWOT analysis, PESTLE analysis and Porter’s Five forces framework. The two types of strategic analysis tools I chose for my research are “What If” Analysis and 5 Whys.

“What If” Analysis:

“What If” analysis is a specific type of scenario analysis. During this analysis, you use brainstorming techniques. Ask multiple “what if” questions to anticipate possible obstacles and the impact they could have on the company’s operations. There are numerous questions that can be asked and answered with “What If” analysis. These range from high-level risk management planning questions, to questions that have very specific measurable impacts. A typical “What If” Analysis could have a purely qualitative analysis or a purely quantitative one (Mind Tools, 2019).

Sensitivity Analysis is a specific form of” What If” analysis that looks at the effect of changes in the value of estimates or assumptions within an existing model. For example, if a company wants to know the impact on the company’s bottom line if they have to reduce prices. The company can manipulate sales figures and find out how much room they have to decrease pries. This analysis can be built into Microsoft Excel which makes it easier to see the effect on sales, margins, and net income if other inputs are changed. From there you can decide which changes are important and which ones need more investigation and planning. You can assume, but this analysis lets you test that assumption.

The step by step “What If” process is, defining the scope of the analysis, identifying the problems that need attention and analyze them further, generate “What If” questions for all the problem areas where the company believes could be affected, then answer to all those “What If” questions by researching, investigating, testing out assumptions and using sensitivity analysis for all those quantitative related scenarios, last the company uses the results to make a decision.

Some of the pros of the “What If” analysis are, being able to make better and more knowledgeable decisions by creating hypothetical situations, brainstorming and estimating the results which allows the company to predict the outcome of their decisions. A disadvantage to this analysis is that it could be expensive to conduct as well as difficult to interpret the results.

5 Whys:

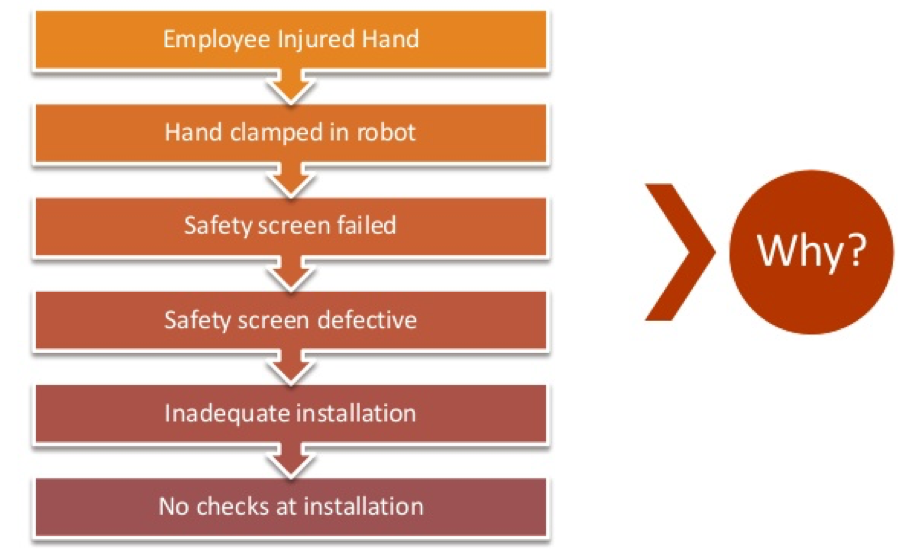

The 5 Whys technique was developed by Sakichi Toyoda in the 1930s. Sakichi is the inventor and founder of Toyota Industries. This method became popular in the 70s and it is still being used by Toyota to solve problems. This technique is simple but an effective and powerful tool. When your company has recurrent and stubborn problems you want to cut through the outward symptoms of the problem to reveal the underlying causes, making sure that you are getting to the root of it and deal with the issue to prevent it from arising again. A company wants to use the 5 whys for troubleshooting, quality improvement and problem solving, but it is most effective when used to solve simple and moderately difficult problem (Mind Tools, 2019). Companies do not want to use the 5 whys technique when dealing with complex or critical problems since these could possibly have multiple causes. The reason being that it can lead the company to pursue a single track or small number of tracks. Also, a more complex or critical problem could need a more in depth approach.

This technique follows a seven step process:

First, get a team together, you want to make sure all team members are familiar with the details of the problem as well as with the process that you are trying to fix. Second, define the problem in action if possible. Converse with your team and write on a whiteboard a short and concise statement that you all agree on, leaving space around it to write answers to the repeated question. An example of this would be your employees not meeting certain deadlines. Step three, ask the first “why?”. Ask the team why the problem is happening, it sounds simple, but it requires thought and intelligent application. Make sure that the answers aren’t guesses of what might be the issue but about things that have actually happened. Once the team has one obvious reason or several possible ones, write them on the whiteboard. Step four, ask “why?” four more times. Base the question according to the answer from the previous question. Here is a quick example of the 5 whys technique:

Step five, know when to stop when asking “why” doesn’t take you any further. once the team has gotten to the root of the problem, a fitting counter-measure becomes evident. Step six, address the root cause, discuss and agree as to what counter-measures will stop the problem from happening again. Step seven, monitor how effective your counter-measures are. If it has eliminated the problem or minimize it. Depending on this, you may need to modify it or repeat the 5 whys process.

Pros of the 5 whys technique are, that its easy to use and apply, practical tool for problem solving. You could get to the root cause relatively fast. Cons of the 5 whys technique are, since it is qualitative, the outcome is subjective. In some cases, members of the team are biased and can skew the results by disregarding present facts.

Using strategic analysis tools to problem solve, address challenges, make improvements or capitalize on opportunities from a R&D, Marketing, Finance and Production perspective during “Competition” Round 1 of the Capsim Core simulation in the future.

The “What If” analysis would fit perfectly during the competition round 1of the Capsim core, since this analysis is usually used when the future is not clear. Creating hypothetical situations such as, what if my production forecast is under? what if production capacity isn’t enough? What if costs increase by 5-10 %? What if the company’s promo and sales budget is not enough? etc. These hypothetical scenarios would help the company plan ahead and come up with a plan in case any of these situations happen. This analysis is part of the decision-making process.

The “5 Whys” technique would be useful to problem solve situations that arise. For example, the company being in the red for “profit”. The first question asked would be “why is the company not profiting”. This could be due to the company not generating enough revenue to catch up to the expenses, the company’s pricing strategy is wrong, the company’s strategy isn’t attracting the right kind of customers, etc. Using the 5 whys technique could help you get to the root of your problem and help you find the right solution so this issue doesn’t happen again, or it might show you that the problem is more complex than expected and needs a more in depth approach.

References

Mind Tools, LTD (2019). “What If” Analysis. Retrieved January 19, 2019, from https://www.mindtools.com/community/pages/article/newTED_76.php

Mind Tools, LTD (2019). 5 Whys. Retrieved January 19, 2019, from https://www.mindtools.com/community/pages/article/newTMC_5W.php

Anderson, S. (2009, December 17). Root Cause Analysis: Addressing Some Limitations of the 5 Whys. Retrieved January 20, 2019, from https://www.qualitydigest.com/inside/fda-compliance-news/root-cause-analysis-addressing-some-limitations-5-whys.html

![]()