What Is Lean?

Lean Philosophy

Lean traces roots back to Henry Ford in early 1900s. Toyota combined the work of Ford and Deming to create: The Toyota Production System.

Lean is not about making you do more work, it’s about getting all the things out of the way that prevent you from doing your work.

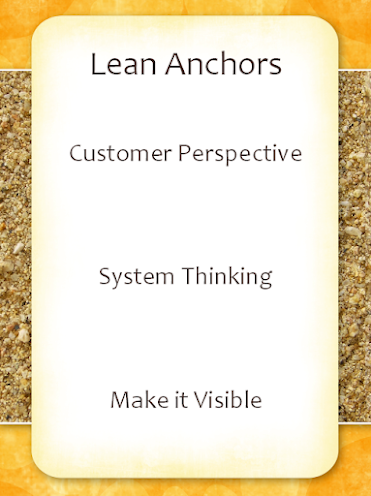

Anchors for Your Lean Journey, Today and Beyond

When thinking about continuing process improvement, Lean suggests to follow the below three anchors:

- Customer perspective: Evaluate situations from the customer perspective.

- System thinking: There is a misconception that Lean just means taking out steps. Lean is a system level philosophy, and optimizing one part does nothing for the whole.

- Making it Visible: Lean has a bias for the visible. If processes aren’t known or seen, we can’t improve them.

Lean Five Principles

The five-step thought process for guiding the implementation of lean techniques is easy to remember, but not always easy to achieve:

- Customer Value: Specify value from the standpoint of the end customer by product family.

- Value Stream: Identify all the steps in the value stream for each product family, eliminating whenever possible those steps that do not create value.

- Flow: Make the value-creating steps occur in tight sequence so the product will flow smoothly from process-to-process

- Pull: As flow is introduced, let customers pull value from the next upstream activity.

- As value is specified, value streams are identified, wasted steps are removed, and flow and pull are introduced, begin the process again and continue it until a state of perfection is reached in which perfect value is created with no waste.

What is Gemba

Gemba is a Japanese word that means- Where the work is done, in a factory it would be the shop floor.

Gemba Boards: Visual management system to encourage ongoing improvement aligned to group, department and/or organizational goal

What is Gemba Walk?

It’s a way to involve leadership giving them the opportunity to visit the floor and observe what is really happening. It helps leadership to observe, gather information, and interact with employees doing the job.

Why Is Lean Important

Companies need to constantly enhance and evolve. Implementing Lean Methodology and Lean tools are proven to improve business and beat the competition. Lean is a business improvement technique which focuses on the actual needs of the customer by preventing waste from being built into the system.

![]()

![]()